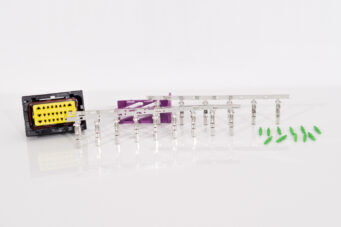

CAN I/O PLC Waterproof PRO V2

go to order options (1128x)

The waterproof CAN I/O PLC Waterproof PRO V2 with 16 I/Os convinces by the various application possibilities in numerous control applications. In addition to eight I/Os that can be configured as inputs or outputs, it offers six analog and two digital inputs. The CAN controller also has integrated protection diodes to limit the free-wheeling voltage generated by the inductive loads.

The module can be used to control four current-controlled proportional valves. The 5 Volt reference output allows additional sensors to be supplied with voltage. The own supply voltage can be measured internally via terminal 30.

Technical details

Inputs and Outputs

| Number of pins | 24 |

|---|---|

| In-/Outputs (total) | 15 |

| Inputs (total) | 7 |

| Inputs (analog) | 6 |

| Inputs (digital) | 1 |

| I/Os (total) | 8 |

| I/Os (Input analog) | 6 |

| I/Os (Input digital) | 2 |

| I/O (Output PWM capable, integrated current measurement INA) | 4 |

| I/O (Output PWM capable) | 2 |

| I/O (Output digital) | 2 |

| Output type high side | 8 |

| Switching current | 3 A @ 85°C |

Interfaces

| CAN interface(s) | 1 |

|---|---|

| Serial Interface(s) | 1 |

Mechanical Properties

| IP rating | IP6K8 |

|---|---|

| Housing material | PA66GF30 |

| Dimensions | 60 × 80 × 30 mm |

Programming

| Programming software | MRS Applics Studio |

|---|

General

| Temperature range | -40 to +85°C |

|---|---|

| Operating voltage | 9-32 V |

| Quiescent current (12V) | 75 µA |

| Quiescent current (24V) | 138 µA |

| Vref current limit | 500 mA |

| Processor architecture | 8 bit |

Markings

Order options

| Order no. | Name |

|---|---|

| 1.128.301.0000 (11283010000) |

5V Ref, KL30-Wake-up, CAN-HS, Type B, Connection RS232

|

| 1.128.301.1000 (11283011000) |

5V Ref, KL15/CAN-Wake-up, CAN-HS, Type B, Connection RS232

|

| 1.128.321.1000 (11283211000) |

5V Ref, KL15/CAN-Wake-up, CAN-HS, Type D, Connection RS485

|

| 1.128.301.1010 (11283011010) |

5V Ref, KL15/CAN WAKE, CAN-HS, DZ128, Connection RS232

|

| 1.128P.301.1000 (1128P3011000) |

5V Ref, KL15/CAN WAKE, CAN-HS, RS232, CANOPEN

|

Contact

Would you like to learn more or are you looking for a specific product?

Then please feel free to contact us.